Silicone gasket custom

Classification:

Service Hotline

Product Details

Product Details

Silicone gasket custom

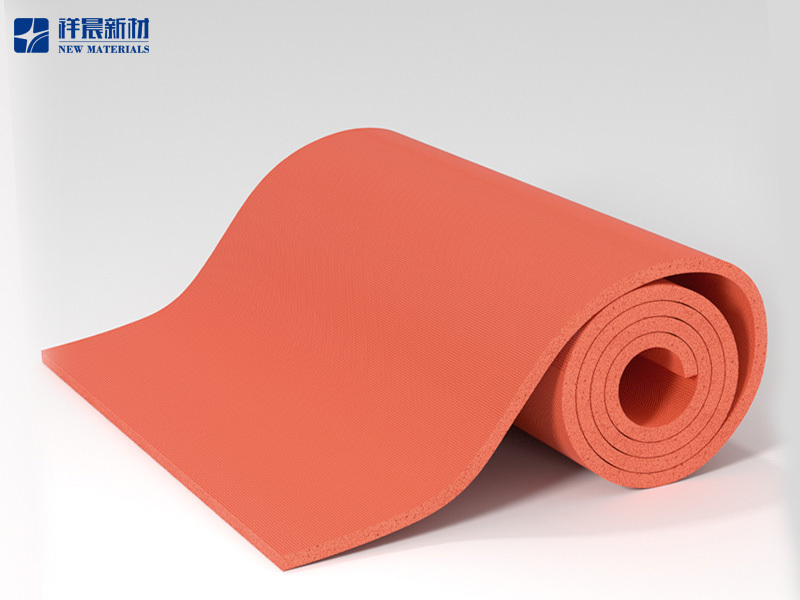

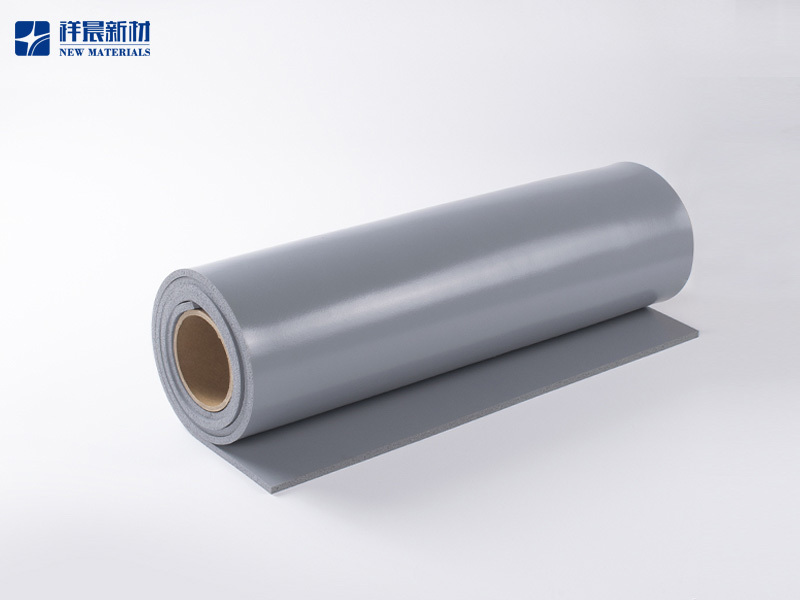

Silicone gaskets are an essential component in many industrial applications, providing a reliable seal between two surfaces. Custom silicone gaskets offer a tailored solution to meet the unique requirements of each application, ensuring optimal performance and longevity. In this article, we will explore the benefits of custom silicone gaskets and the process of designing and manufacturing them.

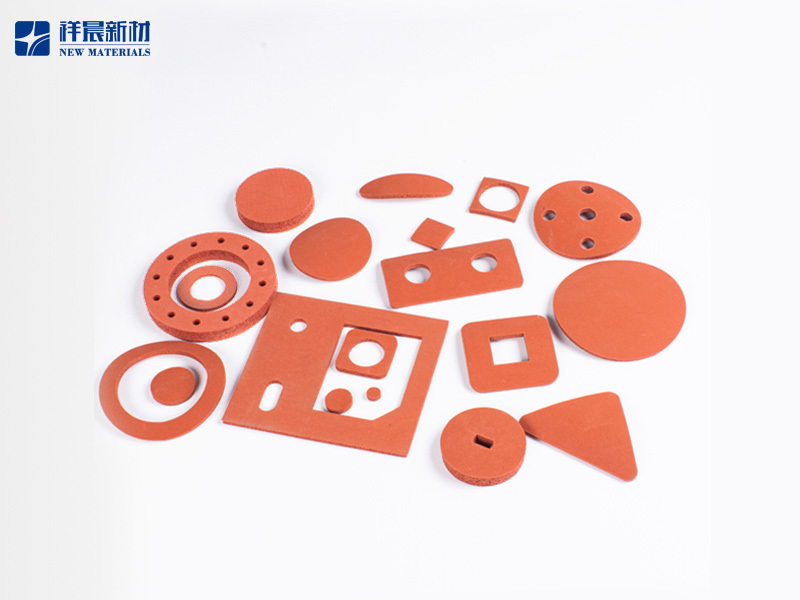

Custom silicone gaskets are designed to fit specific dimensions and shapes, making them ideal for applications where standard gaskets may not provide an adequate seal. By customizing the size, shape, and material of the gasket, manufacturers can ensure a precise fit and optimal performance. This is particularly important in industries where precision and reliability are critical, such as aerospace, automotive, and medical equipment manufacturing.

One of the key benefits of custom silicone gaskets is their ability to withstand extreme temperatures and environments. Silicone is known for its excellent heat resistance, making it suitable for applications where temperatures fluctuate or reach high levels. Custom silicone gaskets can be formulated to meet specific temperature requirements, ensuring they remain effective and durable in challenging conditions.

In addition to temperature resistance, custom silicone gaskets offer excellent resistance to chemicals, oils, and other liquids. This makes them ideal for applications where exposure to harsh chemicals or fluids is common. By customizing the material composition of the gasket, manufacturers can ensure it provides a reliable seal and prevents leaks or contamination.

The process of designing and manufacturing custom silicone gaskets begins with understanding the specific requirements of the application. This includes determining the dimensions, shapes, and materials needed to achieve the desired seal. Once the requirements are established, engineers can create a CAD design of the gasket, taking into account factors such as compression, flexibility, and durability.

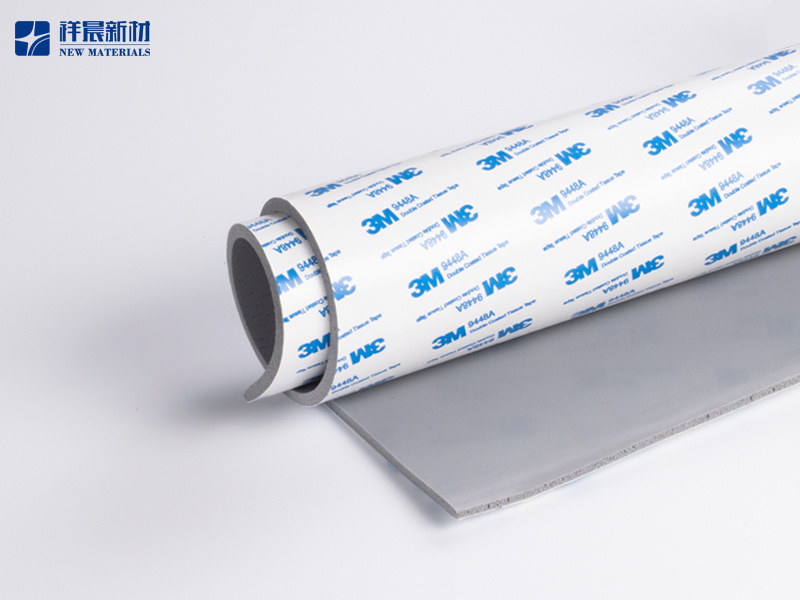

After the design is finalized, the manufacturing process begins. Custom silicone gaskets are typically fabricated using a compression molding or die cutting process, depending on the complexity of the design. The silicone material is carefully molded or cut to the exact specifications of the design, ensuring a precise fit and reliable seal.

Once the gaskets are manufactured, they undergo rigorous quality control testing to ensure they meet the highest standards of performance and reliability. This includes testing for compression set, tensile strength, and resistance to temperature and chemicals. By conducting thorough testing, manufacturers can guarantee that custom silicone gaskets will perform effectively and consistently in the intended application.

In conclusion, custom silicone gaskets offer a versatile and reliable solution for a wide range of industrial applications. By tailoring the size, shape, and material of the gasket to specific requirements, manufacturers can ensure optimal performance and longevity. With their excellent resistance to temperature, chemicals, and liquids, custom silicone gaskets provide a durable and effective sealing solution for critical applications.

Keywords: Silicone foam board | Silicone tube customization | Liquid silicone foam

Core advantages

Core advantages

Independent Research and Development

Xiangchen New Materials has become one of the earliest domestic enterprises to master silicone foam manufacturing technology through independent research and development, successfully realizing industrialization, and breaking the technological monopoly of foreign enterprises

Innovative design

Intensify product research and development innovation, enhance product performance and application areas, combine with the development prospects of the new materials industry, and strive to contribute the strength of Huizhou merchants to the development of the global new materials industry and the green source field...

well appointed

Our development strategy is to pursue craftsmanship and quality, and build a world brand. We have a professional senior technical team, advanced production and processing equipment, and exquisite production technology...

Careful service

Xiangchen provides you with one-on-one service tracking, enjoying 3 days of free sample design, 24-hour fast response service, fast delivery, and short customization cycle...

Product Consulting

Product Consulting

We will contact you within one working day. Please pay attention to your email.