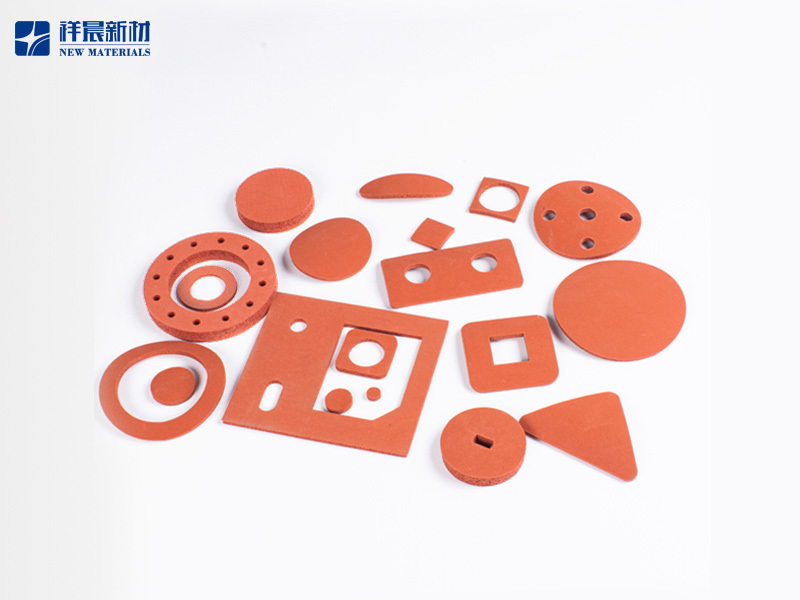

Product Customization Service Selection Xiangchen

Proofing of Various Models

Xiangchen quality stick to, trust comes from our more focused

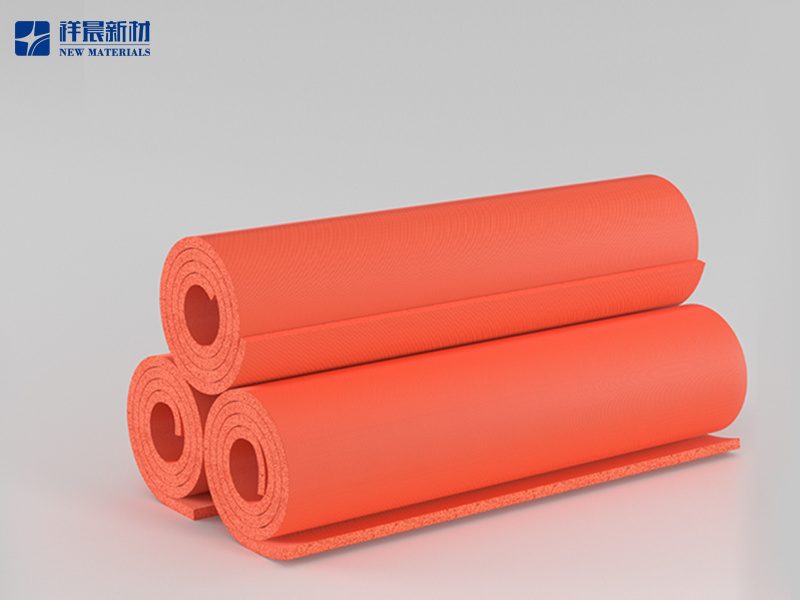

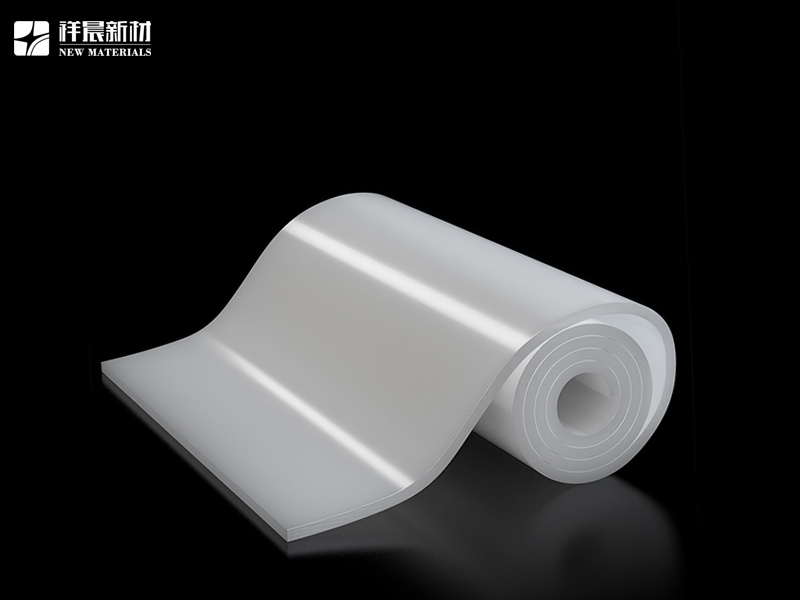

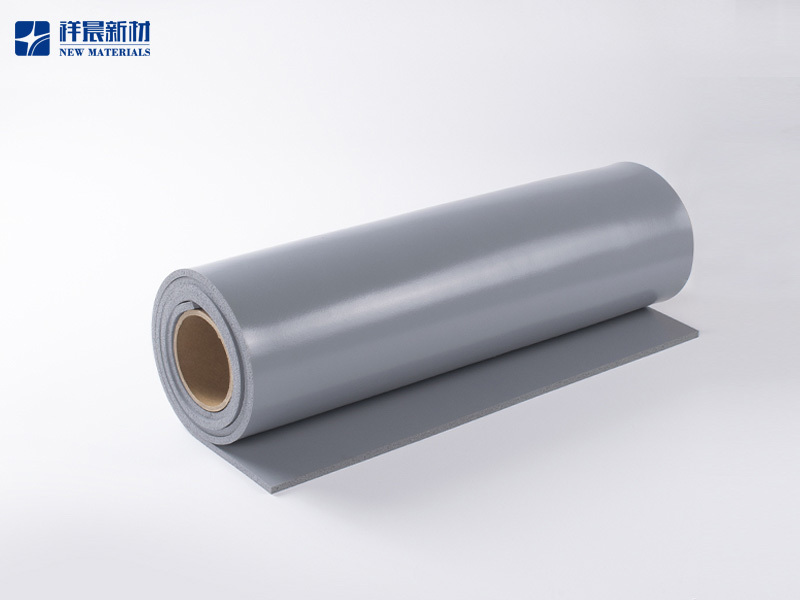

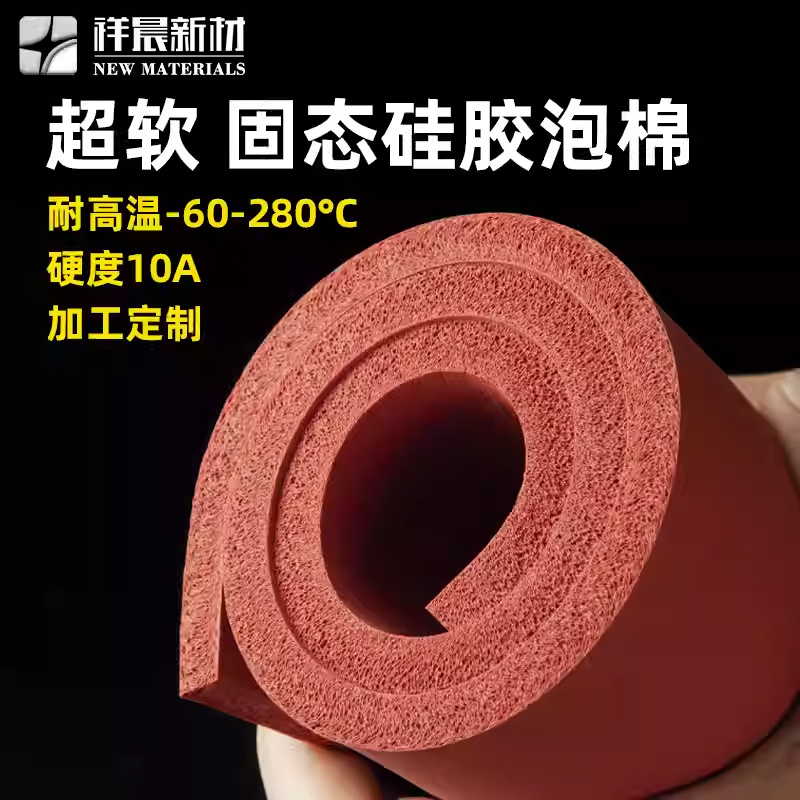

Product Series

Customized service process · Create a better life for people

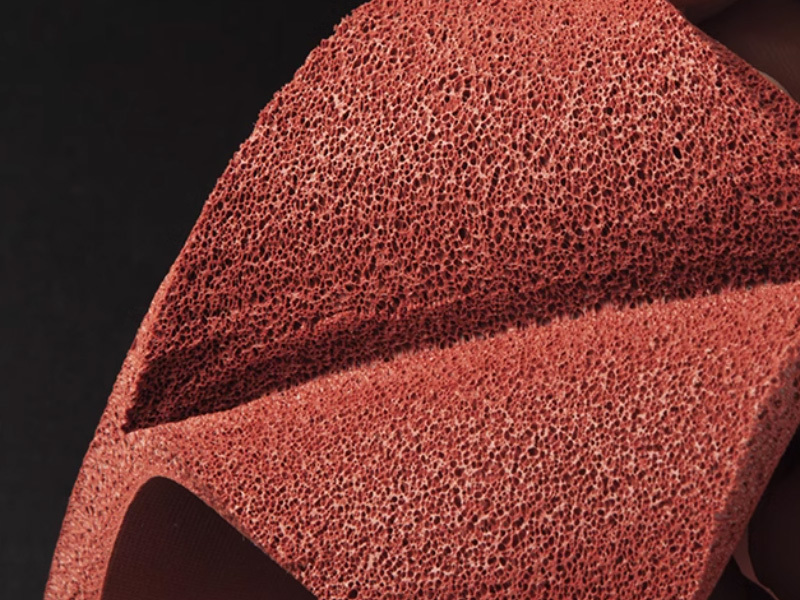

Perfect production and processing equipment and exquisite production technology, through independent research and development to master the silicone foam manufacturing technology

Pre-sales communication

Signing a contract

Single production

Inspection qualified

logistics transportation

After-sales service

The core advantage of Xiangchen · The guarantee of brand quality

Brand tenacious quality, no fear of years baptism

Independent Research and Development

Xiangchen New Materials has become one of the earliest domestic enterprises to master silicone foam manufacturing technology through independent research and development, successfully realizing industrialization, and breaking the technological monopoly of foreign enterprises

VIEW MORE →

Innovative design

Intensify product research and development innovation, enhance product performance and application areas, combine with the development prospects of the new materials industry, and strive to contribute the strength of Huizhou merchants to the development of the global new materials industry and the green source field...

VIEW MORE →

well appointed

Our development strategy is to pursue craftsmanship and quality, and build a world brand. We have a professional senior technical team, advanced production and processing equipment, and exquisite production technology...

VIEW MORE →

Careful service

Xiangchen provides you with one-on-one service tracking, enjoying 3 days of free sample design, 24-hour fast response service, fast delivery, and short customization cycle...

VIEW MORE →

Anhui Xiangchen New Materials

Anhui Xiangchen New Materials Technology Co., Ltd. is a research and development, production, sales, promotion as one of the high-performance new materials technology enterprises. Main Products: Silicone foam board, silicone tube, liquid silicone foam, silicone plate, silicone strip and other products customized services. With the development strategy of "pursuing ingenuity and quality and casting world brands", the company has a professional senior technical team, advanced production and processing equipment and exquisite production technology. After years of research and development and innovation, Xiangchen New Materials has become one of the earliest domestic enterprises to successfully realize industrialization through independent research and development, and has broken the technological monopoly of foreign enterprises.

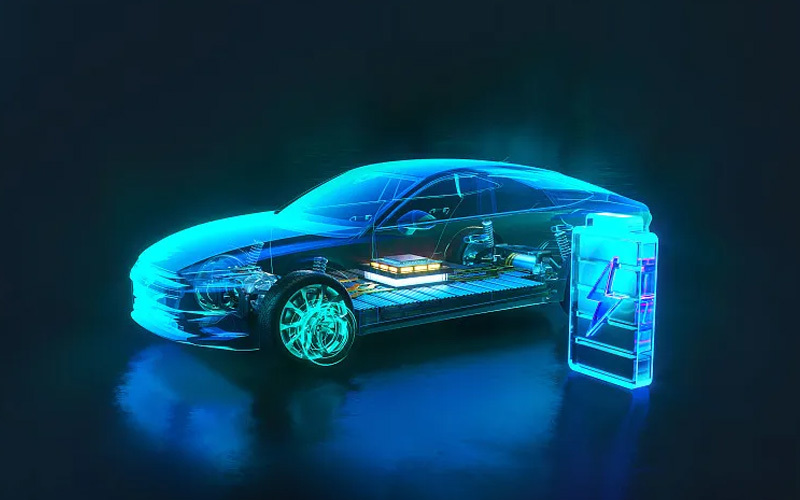

Product application in multiple industries · Repay society with practical actions

Contribute to the development of the global new material industry and the field of green sources

More and more customers choose to cooperate with Xiangchen

Effect reputation continues to rise, market share continues to rise

Have you encountered such a problem?

Difficult selection, many stepping pits, slow delivery, poor quality, poor after-sales and no guarantee

Contact Us

Product unit price is high

Proofing cost is high, product unit price is high

01

Long lead time

The delivery of urgent orders is not on time, affecting the cycle.

02

Supplier instability

Affect brand reputation, lose market

03

Manufacturers lack integrity

Lead to abnormal constantly, the project is difficult to promote

04

Xiangchen New Materials Recent Information Display

Focus on industry dynamics and share real-time information

Faq

Silicone Foam Interface Splicing Technology to Solve the Problem of Water Seepage in Battery Box

Silicone Foam Interface Splicing Technology to Solve the Problem of Water Seepage in Battery Box

The power battery box is sealed with silicone foam, but its interface is easy to loosen and deform, which will cause the danger of water entering the box. Silicone enterprises should be how to conquer?

The power battery box is sealed with silicone foam, but its interface is easy to loosen and deform, which will cause the danger of water entering the box. Silicone enterprises should be how to conquer?

How to distinguish the quality of silicone foam strip?

How to distinguish the quality of silicone foam strip?

You can cut off a piece of foam strip, clamp it with tweezers or scissors, light it with a lighter or match, observe whether the smoke released after burning is pure white or mostly white, and then observe whether the ashes after burning are white or light gray. The ash produced by the combustion smoke of the high-quality silicone foam strip is white or gray, and there is no obvious pungent smell.

You can cut off a piece of foam strip, clamp it with tweezers or scissors, light it with a lighter or match, observe whether the smoke released after burning is pure white or mostly white, and then observe whether the ashes after burning are white or light gray. The ash produced by the combustion smoke of the high-quality silicone foam strip is white or gray, and there is no obvious pungent smell.

The Importance of Foamed Silicone as Sealing Material for Photovoltaic Modules

The Importance of Foamed Silicone as Sealing Material for Photovoltaic Modules

Compared with other general adhesive materials, silicon-based materials-foamed silicone can usually achieve more demanding applications, from applications operating at extreme temperatures to applications operating in harsh environmental conditions. At the same time, foamed silica gel is compatible with the cushioning and thermal insulation properties of foamed materials, and is used as a sealing material for photovoltaic modules, which can produce a series of extraordinary properties and social benefits:

Compared with other general adhesive materials, silicon-based materials-foamed silicone can usually achieve more demanding applications, from applications operating at extreme temperatures to applications operating in harsh environmental conditions. At the same time, foamed silica gel is compatible with the cushioning and thermal insulation properties of foamed materials, and is used as a sealing material for photovoltaic modules, which can produce a series of extraordinary properties and social benefits:

How much do you know about foaming silicone?

How much do you know about foaming silicone?

Silicone foam products have excellent heat resistance, cold resistance, high adsorption performance, high mechanical strength, good thermal stability. Therefore, it is often used in occasions with low temperature, heat resistance, UV resistance, ozone resistance and good electrical insulation properties. For example: automotive, aerospace, computers, machinery and equipment, electronics industry, kitchen appliances, home appliances and other equipment.

Silicone foam products have excellent heat resistance, cold resistance, high adsorption performance, high mechanical strength, good thermal stability. Therefore, it is often used in occasions with low temperature, heat resistance, UV resistance, ozone resistance and good electrical insulation properties. For example: automotive, aerospace, computers, machinery and equipment, electronics industry, kitchen appliances, home appliances and other equipment.

How can silicone foam be used in new energy, 5G base stations, aviation and other industries?

How can silicone foam be used in new energy, 5G base stations, aviation and other industries?

Silicone foam, also known as silicone foam, is a new type of high resilience, low density organic material, with high and low temperature resistance, small compression deformation rate, superior mechanical fatigue resistance, but also has the characteristics of environmental protection, tasteless, waterproof and fireproof surface and other materials. It is widely used in all walks of life and products in daily life.

Silicone foam, also known as silicone foam, is a new type of high resilience, low density organic material, with high and low temperature resistance, small compression deformation rate, superior mechanical fatigue resistance, but also has the characteristics of environmental protection, tasteless, waterproof and fireproof surface and other materials. It is widely used in all walks of life and products in daily life.

After receiving the technical requirements of many customers' drawings, the product clamping line is required to be free of burrs, because many projects often do not carefully review the technical requirements of 2D drawings when receiving the drawings. It looks like a very simple silicone rubber sealing ring, and the unit price of the product is reported to the customer in a few minutes. When the project case is received later, the technical requirements of the drawings are that the sealing ring clamping line is free of burrs, at this time, it is impossible to communicate with customers through technology, so customers will think that we are unprofessional. Then let me popularize the clamping line of silicone rubber sealing ring. Can it be free of burrs?

After receiving the technical requirements of many customers' drawings, the product clamping line is required to be free of burrs, because many projects often do not carefully review the technical requirements of 2D drawings when receiving the drawings. It looks like a very simple silicone rubber sealing ring, and the unit price of the product is reported to the customer in a few minutes. When the project case is received later, the technical requirements of the drawings are that the sealing ring clamping line is free of burrs, at this time, it is impossible to communicate with customers through technology, so customers will think that we are unprofessional. Then let me popularize the clamping line of silicone rubber sealing ring. Can it be free of burrs?